Microstructure Control in Materials

Anyagok mikroszerkezeti tervezése kutatócsoport

A kutatócsoport alaptevékenységei előre definiált tulajdonságokkal rendelkező polikristályos rendszerek fejlesztéséhez kapcsolódnak, amit a termomechanikai gyártási paraméterek változása által kívánnak kontrolláltan befolyásolni. A kutatás fejlett anyagok tervezésére, mikrostruktúrák kísérleti jellemzésére és a technológiai folyamatok modellezésére irányul. Az innovatív gyártási technológiák területén a műszaki paraméterek terméktulajdonságokra gyakorolt hatása kevéssé ismert a hagyományos eljárásokhoz képest, a csoport első eredményei azonban ígéretes kutatási irányokat jeleznek. Fő céljuk többféle hatékony modellezési stratégia integrálása és egy olyan virtuális gyártási platform létrehozása, amely nem csak az anyagok virtuális térben történő előállítását teszi lehetővé, hanem biztosítja a valós gyártási folyamatok irányítását, és lehetővé teszi a gyártási paraméterek in situ megváltoztatását a kívánt végső tulajdonságoktól függően. Ilyen módon a gyártási folyamatoknak több rejtett aspektusa is feltárulhat.

Polikristályos anyagok termomechanikai feldolgozása

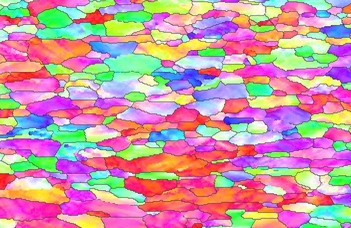

Mezoszkópos átalakulások vizsgálata: szövetszerkezeti és kristálytani szempontok

Részletek:

https://doi.org/10.1016/j.msea.2010.09.023

https://doi.org/10.1016/j.scriptamat.2012.10.039

https://link.springer.com/article/10.1007/s10853-014-8068-8

https://doi.org/10.1016/j.msea.2023.144768

https://doi.org/10.1016/j.msea.2022.143145

https://doi.org/10.1016/j.actamat.2020.03.04

https://doi.org/10.3390/ma17246057

Anyagok virtuális termomechanikus feldolgozása

Részletek:

https://link.springer.com/article/10.1007/s11661-013-2021-3

https://doi.org/10.3390/met9101098

https://link.springer.com/article/10.1007/s12289-016-1330-7

https://doi.org/10.3390/app13074359

https://iopscience.iop.org/article/10.1088/1757-899X/1121/1/012046

https://doi.org/10.3390/met15010011

Anyagok kristálytani textúrájának és textúra-alapú tulajdonságok fejlődésének modellezése a kontinuummechanika és a kristályképlékenység elmélet elvei alapján

Full Constraints Taylor modell, Visco-Plastic Self-Consistent modell, Advanced Lamel modell, Cluster V modell.

A hőkezelési folyamatok során kialakuló szövetszerkezet kristálytani jellemzőinek modellezése. Fémek anizotrop viselkedésének modellezése különféle kristályképlékenység elmélet megközelítésekkel.

Részletek:

https://doi.org/10.1016/j.actamat.2008.01.042

https://doi.org/10.1016/j.msea.2008.03.005

https://doi.org/10.1016/j.ijplas.2014.08.009

https://doi.org/10.1016/j.actamat.2015.05.035

https://doi.org/10.1080/02670836.2016.1180742

Szubszerkezet evolúciójának elemzése indentálási technikák és numerikus megközelítések által

.png)

Szubszerkezet vizsgálata mikro- és nanoindentálási technikákkal.

Diszlokációs sűrűség alakulásának modellezése a deformált fémes rendszerekben különböző numerikus megközelítésekkel.

Részletek:

https://doi.org/10.3390/met11101571

https://doi.org/10.1016/j.matchar.2022.112166

https://doi.org/10.1016/j.msea.2023.144768

https://doi.org/10.1016/j.matchar.2025.114764

Lágyulási folyamatok kinetikájának és lágyulási jelenségek elemzése az anyagokban

.png)

Részletek:

https://mmelo.eu/event/online-lecture-by-prof-jurij-sidor/

https://doi.org/10.1016/j.actamat.2011.05.050

https://doi.org/10.3390/ma16175760

https://iopscience.iop.org/article/10.1088/1742-6596/2635/1/012031

https://www.scientific.net/SSP.353.53

https://iopscience.iop.org/article/10.1088/1757-899X/375/1/012028

Anyagok jellemzése pásztázó elektronmikroszkóppal, visszaszórt elektron diffrakcióval és elektrondiszperzív analízissel.

A mikroszkóp EBSD és EDX detektorokkal is fel van szerelve, amelyek lehetővé teszik az anyagok krisztallográfiai textúra mérését és kémiai összetétel elemzését.

Mechanikai tulajdonságok vizsgálata makroszkópos, mikroszkópos és nanoskálákon

Makroszkópos tulajdonságok meghatározása szakító/hajlító és Charpy-vizsgálatok által: folyáshatár, szakítószilárdság, hajlítószilárdság, keményedési paraméterek, Young-modulus, Poisson-tényező, szívósság, Lankford-érték, ütési energia.

Mikroszkópos tulajdonságok: Vickers és Knoop mikrokeménység 10 gf és 1 kgf közötti terhelésekkel alkalmazásával.

Lokális indentálási mérések Berkovich tippel (terhelés ~ mikronewton).

Gyártási folyamatok modellezése numerikus megközelítések: végeselem-modellek, vonal-áramlási modellek, kristályképlékenységi modellek, újrakristályosodási modellek.

A szövetszerkezet kristálytani átalakulását és keményedési folyamatokat szimuláljuk kristályképlékenységi kódokkal.

Az újrakristályosodás és a lágyulási jelenségek kinetikáját szimuláljuk a csoportunkban kidolgozott numerikus megközelítésekkel.

- Prof. Dr. Jurij Sidor, DSc, Csoport vezető

- Dr. Fenyvesi Dániel, egyetemi docens, vezető kutató

- Dr. Borbély Tibor, egyetemi docens, vezető kutató

- Dr. Herbáth Beáta, egyetemi adjunktus, vezető kutató

- Bátorfi János, PhD hallgató, fiatal kutató

- Tóth János, technikus

- Számos BSc és MSc hallgató részt vesz a projektek részfeladatok megvalósításában.

Projektek

- Security and data protection in the fields of material technology, industry 4.0 and energy engineering (2022-2025, pillar 3 in the project no. TKP2021-NVA-29 “Protection of high integrity national services and industrial infrastructures using cybersecurity, technological and legislative instruments”)

- Innovative processing technologies, applications in energy engineering, and wide-range microstructure investigation techniques (2017-2021, workgroup 5 in the project EFOP-3.6.1-16-2016-00018 “Improving the role of research + development + innovation in the higher education through institutional developments assisting intelligent specialization in Sopron and Szombathely”)

- OTKA. Modelling and complex experimental evaluation of texture dependent solid phase reactions in metallic systems (Project nr.: 119566)

- OTKA. New avenues of production of bulk and composite nanostructured metals; experiments,characterization, modelling. (Project nr.: 143800)

Ipari projektek

- 2016: Microstructural investigation of MnZn ferrite. Industrial Partner: EPCOS Kft., TDK Group Company.

- 2019: Scanning electron microscopy: material examination by SE/BSE and EDX detectors. Industrial partner: Schaeffler Savaria Kft.

- 2020: Determination of mechanical properties by tensile, bending and Charpy methods. Industrial partner: Alpok Projekt Kft.

- 2021: Determination of microstructural differences by microhardness, scanning and optical microscopy. Industrial partner: BPW-Hungária Kft.

- 2021: Assessment of properties by microhardness and SEM. Industrial partner: iSi Automotive Hungary Kft.

- 2022: Determining the thickness of different layers using an optical microscope. Industrial partner: BPW-Hungária Kft.

- 2022: Fracture surface studies: Optical and Scanning Electron Microscopy. Industrial partner: Schaeffler Savaria Kft.

- 2022-2024: Development of Parabolic Spring. Industrial partner: BPW-Hungária Kft.

- Sidor, J., Miroux, A., Petrov, R. and Kestens, L. (2008) ‘Microstructural and crystallographic aspects of conventional and asymmetric rolling processes‘, Acta Materialia, 56, pp. 2495–2507.

- Sidor, J., Petrov, R. H. and Kestens, L. A. I. (2010) ‘Deformation, recrystallization and plastic anisotropy of asymmetrically rolled aluminum sheets‘, Materials Science And Engineering A, 528, pp. 413–424.

- Sidor, J. J., Verbeken, K., Gomes, E., Schneider, J., Calvillo, P. R. and Kestens, L. A. I. (2012) ‘Through process texture evolution and magnetic properties of high Si non-oriented electrical steels‘, Materials Characterization, 71, pp. 49–57.

- Sidor, J. J., Decroos, K., Petrov, R. H. and Kestens, L. A. I. (2015) ‘Evolution of recrystallization textures in particle containing Al alloys after various rolling reductions: experimental study and modeling‘, International Journal of Plasticity, 66, pp. 119–137.

- Chakravarty, P., Pál, Gy., Sidor, J. J. (2022) ‘The dependency of work hardening on dislocation statistics in cold rolled 1050 aluminum alloy‘. Materials Characterization, 191, pp. 112166:1–112166:13.

http://smi.inf.elte.hu/laboratechnika/